Zigong Guotai Huarong New Materials Co., Ltd

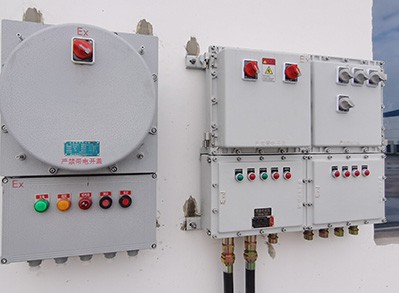

Zigong Guotai Huarong New Materials Co., Ltd., as a leading enterprise in the field of lithium battery electrolytes, has a production environment involving highly corrosive, flammable, and explosive media such as high-purity solvents and lithium fluoride. Based on the technical accumulation in the field of fine chemical explosion prevention, Kingdon Electric has created customized safety protection systems for synthesis workshops, tank areas, and filling lines.For the volatile gas environment of electrolyte, Kingdon adopts Ex d IIC T4 explosion-proof distribution system, with core equipment certified by ATEX and IECEx, customized 316L stainless steel explosion-proof shell and fluorocarbon spraying process, and corrosion resistance level reaching ANSI/NACE MR0175 standard. The project deploys 42 explosion-proof intelligent control cabinets and 120 sets of intrinsic safety sensors, integrating an AI sound and light warning system to monitor VOCs concentration and equipment insulation status in real time, reducing the leakage response time to 0.1 seconds. Innovative application of explosion-proof LED linear lighting system, with a light efficiency of 160lm/W and a lifespan of over 80000 hours in lithium hexafluorophosphate corrosive environment.The engineering team synchronously implements a three-level electromagnetic shielding scheme to ensure zero interference in the DCS control system. After the renovation, the explosion-proof compliance rate of the factory area is 100%, the equipment failure rate has decreased by 55%, and the annual maintenance cost has been saved by more than 3 million yuan, setting a safety benchmark for intelligent manufacturing of new energy materials. Jindun will continue to empower the high-quality development of the green energy industry with innovative explosion-proof technology.